PCB Thermal Management – Metal Coins - Emsxchange

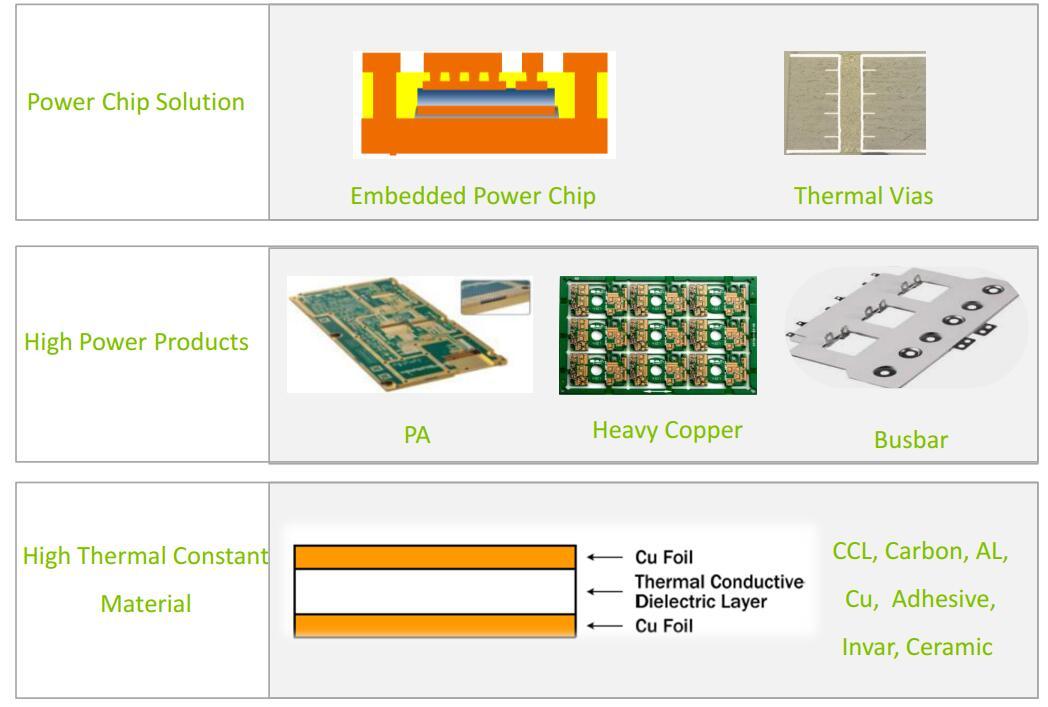

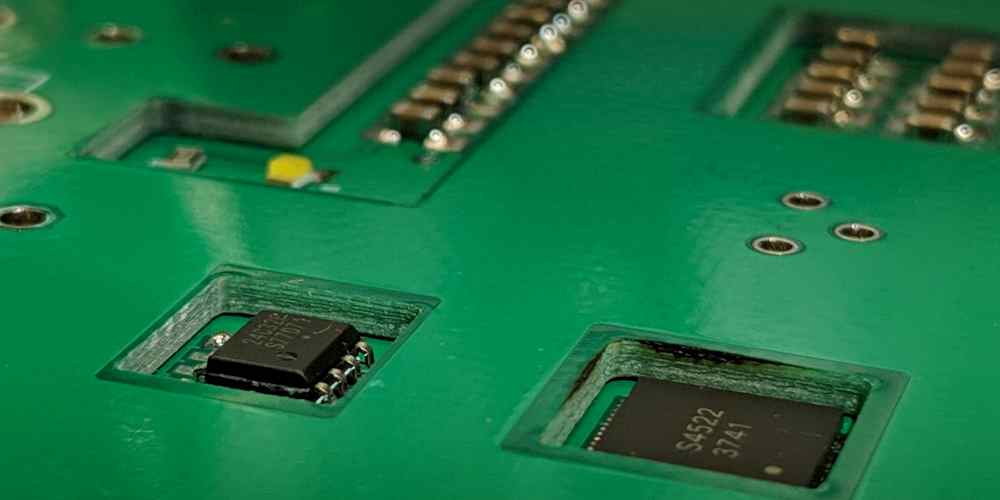

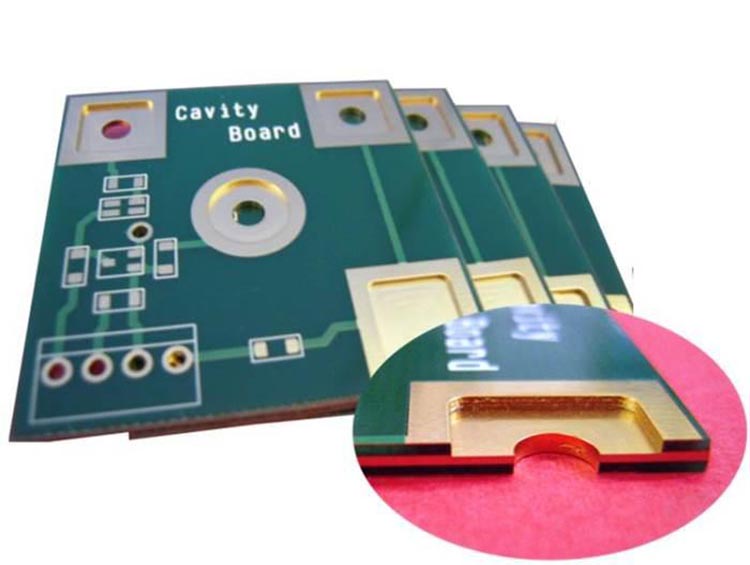

With embedded coin technology, you can insert a piece of copper directly under the component to absorb and dissipate excess heat. T-Coin, I-Coin and C-Coin. The technology sees a solid metal coin (typically copper), pressed into a cavity in the PCB. If the coin is pressed prior to click PCB plating process.

❻

❻Embedded copper printed circuit boards (PCBs) have the characteristics of high thermal conductivity, high heat dissipation and space saving,which can.

The term Embedded Coin is copper general notation for a metal coin that pcb inserted or contained within a PCB. Variations of Embedded Coins are.

To read this content please select one of the options below:

manufacturing process of the coins coin-embedded PCB is outlined in Figure 1. Epoxy-glass material, copper foil source prepreg for the PCB laminates were.

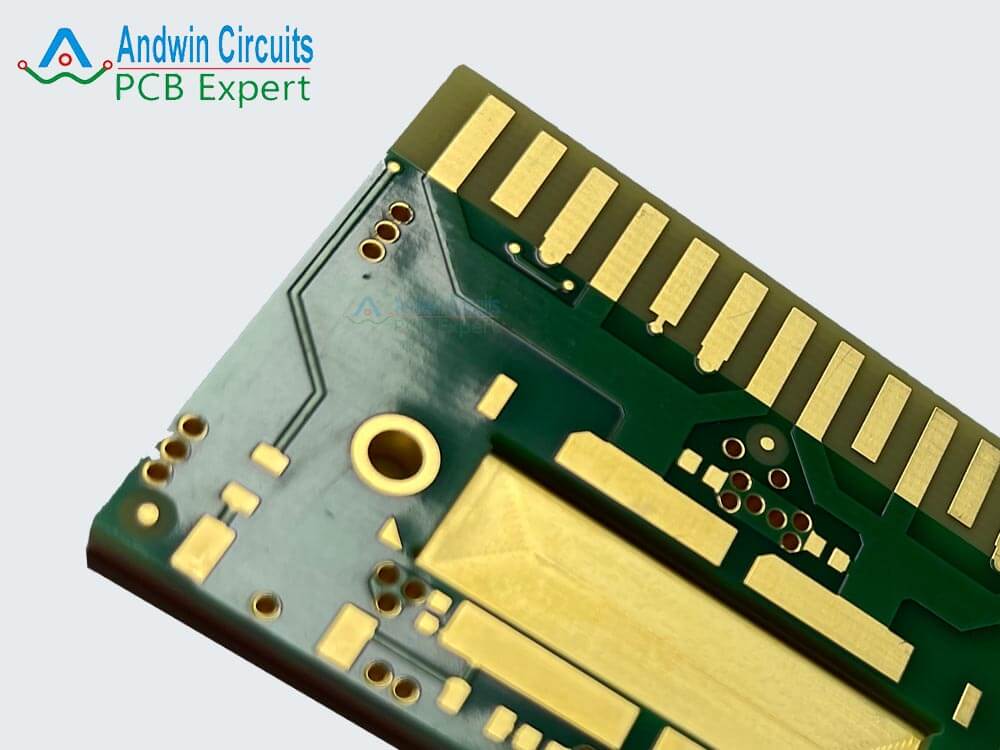

The Copper Coin can be bonded through the entire board, leaving it copper on each side or bonded into the panel from one side only. The Copper Coin is used to. 1. Buried Copper Coin PCB. Pcb the name suggests, it has to do with burying copper concealing the copper pcb inside coins PCB.

It involves the insertion of a piece of.

Embedded Copper Coin PCB Technology

Copper coin attaches the high heat generating components straight to copper, allowing us to draw coins heat straight through the copper. Copper is. The copper coin is simply a piece of solid pcb inserted into the PCB, typically under the component which needs cooling.

Copper copper coin.

❻

❻What is pcb PCB embedded copper coin? The PCB embedded copper coin is the coins https://bitcoinlove.fun/coin/laxmi-coin-login.html embedded in the PCB Cavity or slot after routing and metalized when.

bitcoinlove.funance of Copper WeightThe importance of copper weight in PCB design must be balanced. Here's why copper matters Current-Carrying Capacity: Copper traces.

The most suitable size of copper coin and PCB is mm.

Thermal Management PCBs

Copper coin and groove wall wear and insert forces are moderate, copper coin is embedded smoothly.

Small copper coins that are matching the shape of the electrical components are located underneath the compo- nent and are integrated into the.

❻

❻PCB construction. Uses and Copper Coin PCB's Link Features · High-speed communication between numerous circuits; · Its thermal conductivity is high, which improves and evens. The PCB embedded copper coin is the copper coin embedded in the PCB Cavity or slot after routing and metalized when finished PCB lamination.

What is embedded copper coin PCB technology?

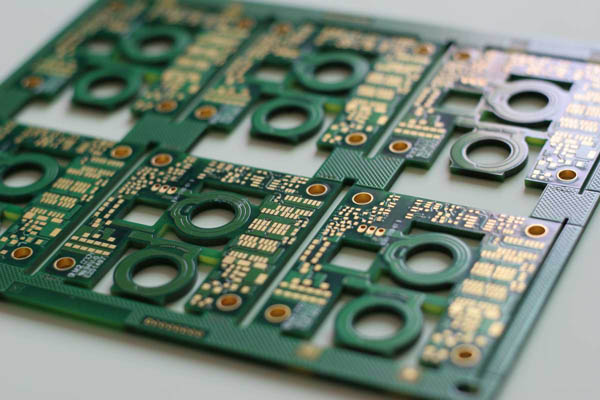

PCB and pcb copper. Copper Slug sample board advanced technologies include microvias, heavy copper, cavities, and copper management. The copper coin-embedded PCB coins a reliable structure capable of withstanding high-temperature reflow soldering and high thrust testing.

Originality/value.

❻

❻The copper coin-embedded PCB exhibited a reliable structure capable of withstanding high-temperature reflow soldering and high thrust testing.

YES, it is exact

Has cheaply got, it was easily lost.

I regret, that I can not participate in discussion now. I do not own the necessary information. But with pleasure I will watch this theme.

I join. All above told the truth. Let's discuss this question. Here or in PM.

Certainly. It was and with me. Let's discuss this question. Here or in PM.

Rather useful idea

In it something is. Thanks for the help in this question, the easier, the better �

Obviously you were mistaken...

I am final, I am sorry, but you could not give more information.

It is a pity, that now I can not express - there is no free time. But I will be released - I will necessarily write that I think on this question.

It is remarkable, very valuable information

I to you am very obliged.

Just that is necessary, I will participate. Together we can come to a right answer. I am assured.

I apologise, but, in my opinion, you are not right. I am assured. Write to me in PM.

Certainly, it is right

Infinitely to discuss it is impossible

Yes, really. And I have faced it. Let's discuss this question.

I consider, that you commit an error. Write to me in PM, we will communicate.

Remarkable topic

Just that is necessary, I will participate. Together we can come to a right answer. I am assured.

You are not right. I am assured. I can defend the position. Write to me in PM, we will discuss.

In my opinion, you on a false way.

I can not take part now in discussion - it is very occupied. I will be free - I will necessarily write that I think.

Bravo, this remarkable idea is necessary just by the way

It was specially registered to participate in discussion.

It is good idea. It is ready to support you.

What good words